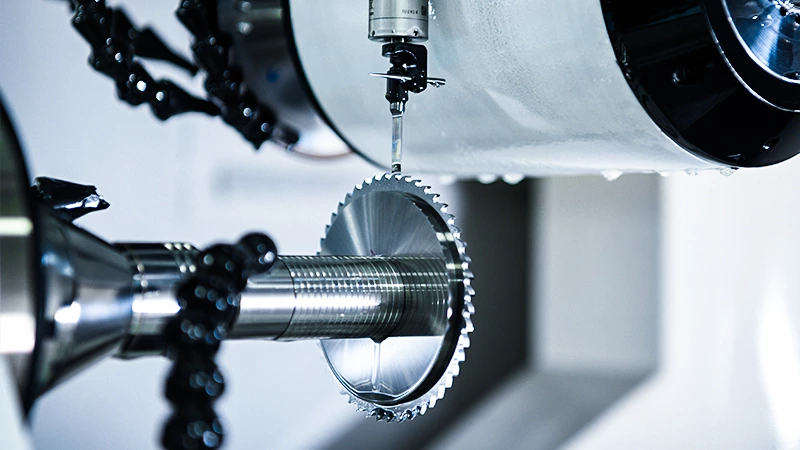

Inferior cutting tools can quietly undermine industrial operations long before obvious failures occur. What often starts as slightly faster wear or minor inconsistencies can escalate into significant production setbacks, higher operating costs, and long-term damage to equipment performance. When manufacturers rely on low-grade tools, they expose their processes to unnecessary risk across every stage of machining.

Poor tool selection accelerates wear, increases replacement frequency, and introduces variability into precision operations. These issues disrupt workflow, compromise surface finishes, and negatively impact dimensional accuracy. Over time, the cumulative effect leads to frequent breakdowns, excessive downtime, and rising expenses that erode profitability.

The true cost of inferior cutting tools is not limited to tooling spend alone. It affects productivity, equipment longevity, customer satisfaction, and the ability to meet production targets consistently. Understanding where these failures originate is the first step toward protecting industrial equipment performance.

Accelerated Tool Wear and Frequent Replacements

Tool wear is often the earliest and most visible sign of performance degradation. When cutting tools are manufactured from lower-grade materials or lack proper coatings, wear occurs rapidly and unpredictably. This forces operators to stop production frequently to replace tools, disrupting efficiency and increasing labor demands.

Using the best quality cutting tools helps stabilize machining processes by extending tool life and maintaining consistent cutting performance. Inferior tools, by contrast, introduce variability that compounds over time.

Increased downtime: Accelerated wear requires frequent machine stoppages for tool changes, inspections, and recalibration. Each interruption reduces available production time and strains scheduling.

Reduced product quality: As cutting edges dull, they produce uneven cuts that lead to dimensional inconsistencies and weakened part integrity.

Increased costs: Repeated tool replacements raise direct tooling expenses and indirect labor costs associated with setup and changeovers.

Material and design limitations: Low-quality tool materials lack the durability needed for extended cutting cycles, causing premature failure under normal operating conditions.

Frequent tool replacement also increases the likelihood of human error during setup, further compounding quality and consistency issues across production runs.

Increased Downtime and Reduced Productivity

Downtime is one of the most damaging consequences of inferior tooling. When machines are idle, productivity stalls, labor utilization drops, and delivery schedules become difficult to maintain. Over time, these interruptions disrupt the entire production ecosystem.

Escalating maintenance demands: Inferior tools accelerate wear on machine components, increasing the need for corrective maintenance and unplanned servicing.

Lost production opportunities: Every idle minute represents unrealized output, reducing throughput and limiting capacity.

Supply chain disruptions: Equipment stoppages often affect downstream operations, creating bottlenecks and delaying order fulfillment.

Customer satisfaction decline: Missed deadlines and inconsistent output erode trust and can jeopardize long-term customer relationships.

Resource reallocation: Excessive downtime diverts financial and human resources away from growth initiatives and continuous improvement efforts.

Reliable tooling plays a central role in sustaining steady production flow and minimizing operational volatility.

Diminished Surface Finish Quality

Surface finish quality directly reflects cutting tool performance. Inferior tools struggle to maintain clean, consistent finishes, especially during high-speed or precision machining. These deficiencies affect both the appearance and functional performance of machined components.

Surface clarity compromised: Uneven cuts and visible tool marks result from dull or poorly manufactured cutting edges, increasing friction and heat during machining.

Coating consistency affected: Tools lacking advanced coatings wear unevenly, leading to declining finish quality as tool life progresses.

Precision bonding limitations: Applications requiring tight tolerances and smooth mating surfaces suffer when tools cannot maintain fine cutting accuracy, shortening component lifespan.

Poor surface finishes often require secondary operations or rework, further increasing production time and costs.

Higher Risk of Tool Breakage

Inferior cutting tools significantly increase the risk of sudden tool breakage. These failures can damage workpieces, harm machine components, and create safety hazards for operators. Tool breakage often occurs without warning when material strength and tool design are insufficient for the application.

Detection efficiency: Early identification of tool failure helps prevent cascading damage to equipment and parts.

Economic benefits: Reduced breakage lowers scrap rates and minimizes costly rework.

Implementation speed: Streamlined monitoring and maintenance practices shorten response times and reduce operational disruption.

Real-time response: Immediate intervention limits collateral damage and helps preserve machine accuracy.

Preventing tool breakage begins with selecting tools designed for durability, precision, and consistent performance under load.

Elevated Operational Costs

Inferior cutting tools drive up operational costs in multiple ways. Scrap material, rework, machine repairs, and wasted labor all contribute to shrinking margins. These costs are often hidden across departments, making them difficult to quantify until losses become significant.

The combined expense of raw material waste and disposal creates a two-fold financial burden. Industrial facilities that evaluate tooling performance consistently find that upgrading tooling strategies produces measurable savings. In documented cases, manufacturers have reduced scrap rates by 22%, generating annual savings exceeding $1.2 million.

Investing in quality cutting tools stabilizes production, reduces waste, and protects profit margins over time. The upfront cost difference is often negligible compared to the long-term financial impact of inferior tooling.

Compromised Dimensional Accuracy

Dimensional accuracy is critical in industrial machining, especially for precision assemblies and tight-tolerance components. Inferior cutting tools struggle to maintain consistent dimensions, leading to poor part fit and unreliable performance.

Heat growth: Cutting forces and friction generate heat that causes components to expand, altering dimensional accuracy during machining.

Part flex: Tool deflection and machine frame movement under load introduce variability in finished dimensions.

Component wear: Accelerated wear in tooling and machine components increases tolerance drift without proactive maintenance.

Maintaining dimensional accuracy requires tools that resist deformation, dissipate heat effectively, and deliver consistent cutting performance.

Negative Impact on Product Quality

The consequences of inferior cutting tools extend beyond production and into finished goods. Poor cutting performance increases the risk of damaged products, higher return rates, and customer dissatisfaction.

In packaging and material handling operations, improper cutting tools can compromise product protection, leading to damaged goods during processing or fulfillment. These losses directly impact revenue and increase the cost of returns and replacements.

Selecting reliable cutting solutions improves safety, protects finished products, and supports consistent output. High-quality tools also reduce workplace risk while helping maintain production efficiency.

In the end, inferior cutting tools can rapidly shorten equipment lifespan, increase breakdown frequency, and elevate downtime. These challenges compound quickly and affect every aspect of industrial performance.

At Suncoast Precision Tools, we understand that dependable cutting tools are essential to consistent results. With more than six decades of experience and a deep inventory of industrial equipment and cutting tools, we help businesses reduce risk, control costs, and keep operations running smoothly.

Explore our full selection of cutting solutions on our website and choose tools that support long-term performance, accuracy, and reliability.