At a glance:

- OKUSLIDE® liners reduce surface erosion by minimising direct contact with abrasive materials.

- It prevents material buildup and corrosion with a low-friction surface, reducing maintenance needs.

- OKUSLIDE® liners shield against moisture and acids, preventing rust formation.

- It lowers tipping angle and time, reducing hydraulic system wear and ensuring safe and smooth operations.

Truck bed maintenance is a continuous issue for businesses that use heavy-duty haulage like mining, agriculture, waste management, and construction. A truck bed’s longevity is greatly decreased by excessive wear and tear, accumulation of debris or moisture leading to corrosion and frequent exposure of heavy and abrasive loads. These factors result in higher repair costs and frequent maintenance.

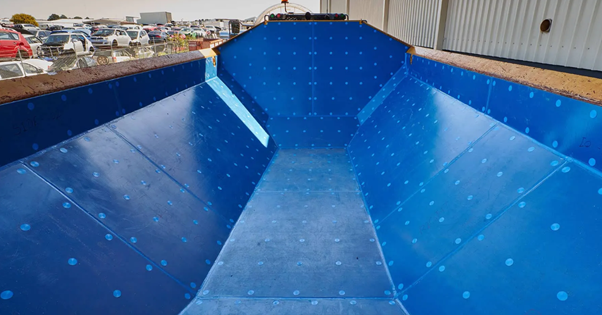

This is where OKUSLIDE® liners come in. An ultra-high molecular weight polyethylene (UHMWPE) liner that surpasses the rest, OKUSLIDE® is designed to reduce friction, minimise material hangup, and protect truck beds from wear and tear. But how does it specifically extend the maintenance cycle of a truck bed?

By Protecting the Truck Bed from Abrasive Wear

One of the biggest problems that heavy, abrasive material carrying truck beds (such as gravel, metal ore, and construction debris) face is the rapid erosion of the surface. Truck beds made of steel or aluminum are very susceptible to scratches, dents, and corrosion after some time of heavy usage.

An OKUSLIDE® liner safeguards the bed by dispersing the shock and reducing direct contact of the truck bed with the material. It is built from UHMWPE and has increased abrasion resistance, twice as much as of steel and 5 times more than aluminium. Because of which the truck bed lined with OKUSLIDE® stays in great condition for an extended period of time.

By Reducing Material Sticking and Buildup

Material buildup is also a top cause of frequent truck bed maintenance, especially with sticky materials such as clay, coal, or wet grain. Since materials stick to the truck bed surface, they cause uneven wear and tear patterns, hence resulting in localised corrosion and structural weakening.

OKUSLIDE® is engineered with a low friction coefficient, due to which materials slide off easily. They are 60% more slippery than alloys and 70% more than steel. This avoids material sticking and buildup, removes the need for operators to clean the truck bed manually, and prevents long-term structural damage, hence longer maintenance cycle.

By Minimising Corrosion and Rust Formation

Standard truck beds, especially those made of steel, are prone to rust and corrosion when their protective coatings are compromised. This process accelerates with exposure to water and acidic substances which is more common in agricultural industry. Corrosion would imply the structural integrity of the truck bed is constantly being undermined, requiring constant repairs or complete replacements.

OKUSLIDE® truck bed liners made of UHMWPE creates a protective barrier between the truck bed and transported materials, preventing direct exposure to moisture and chemicals which minimises rust formation. UHMWPE is naturally corrosion-resistant, ensuring that the metal underneath remains shielded from environmental factors that cause rust.

Other Benefits of OKUSLIDE® Truck Bed Liners

While OKUSLIDE® liners are of great help in extending the maintenance cycle of truck beds, their benefits extend to other areas such as:

Lower Tipping Angle for Safer Unloading

Beds with no liner usually need higher tipping angles to achieve a full load discharge. The higher angle causes undue stress on the hydraulic system, which results in quicker wear and tear of the truck’s tipping system.

OKUSLIDE® liners eliminate this issue by allowing materials to slide out easily, with less tipping angle. A decrease in the tipping angle not only extends hydraulic system life but also improves safety by reducing the likelihood of truck instability and rollover.

Reduced Tipping Time for More Deliveries

Without a liner, materials often stick to the truck bed, slowing down the unloading process. Drivers may need to wait longer for the load to clear or even stop to manually dislodge leftover material.

OKUSLIDE® liners eliminate this issue by allowing materials to slide out effortlessly, reducing tipping time. A faster discharge means less time spent waiting at the job site and more time on the road, completing deliveries efficiently. This not only improves turnaround times but also reduces fuel consumption and operational delays.

OKUSLIDE® liners significantly prolong the maintenance cycle of truck beds by minimising wear, avoiding buildup, and preventing corrosion. In addition to that, operating efficiency is enhanced as operators spend more time on the road and less time in the repair shop or tipping the materials. It also ensures a safe operation, reducing the tipping angle.

For an efficient installation of OKUSLIDE® liners on your truck beds or any other type of application, reach out to their expert team today.